welcome you visit our company at any time, or watch our online video factory. We are very convenient for you to understand that our company hopes to get your approval and have the opportunity to cooperate!

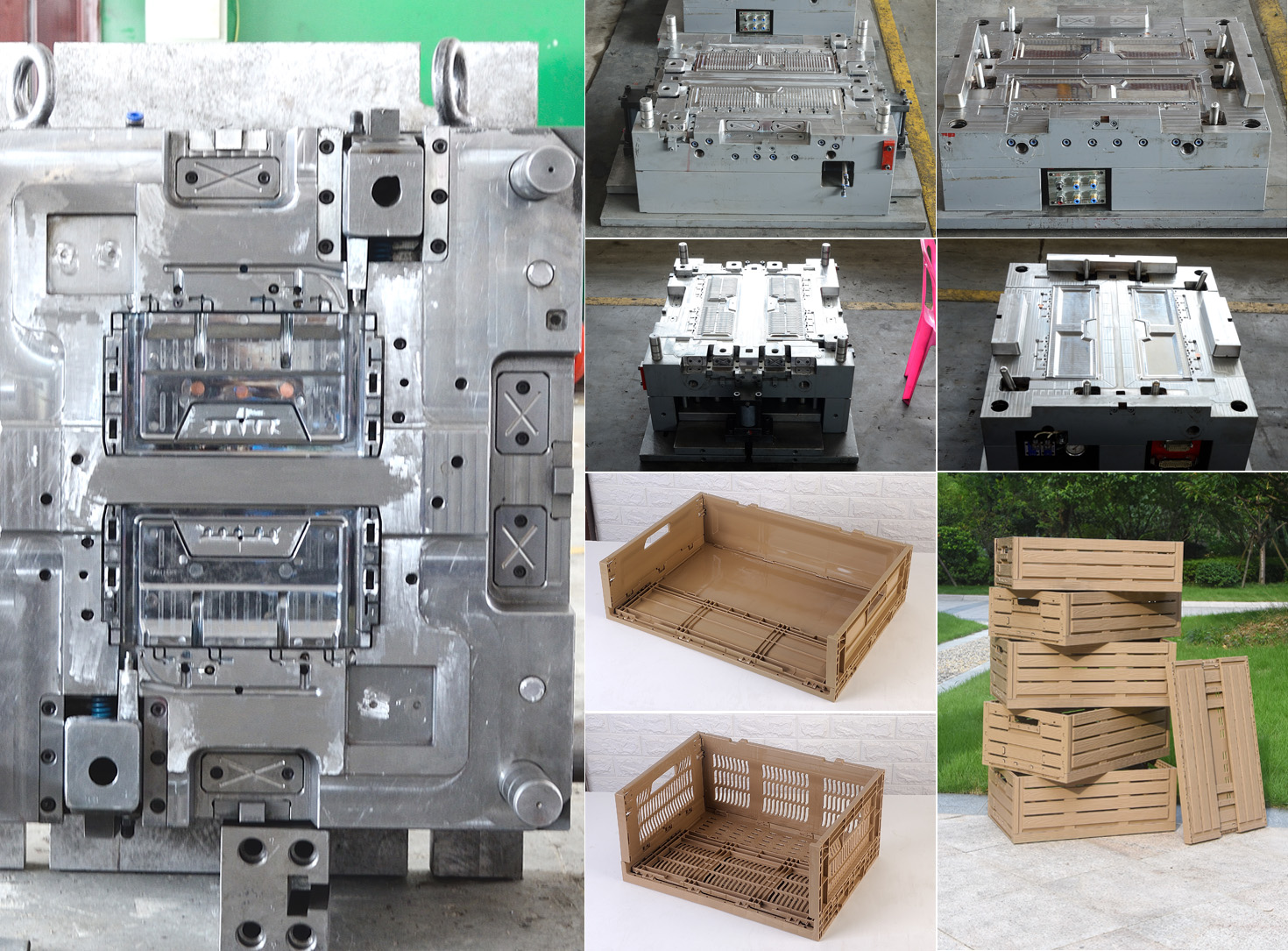

Mold processing

After the confirmation of the mold drawing, start to make,including steel preparation, CNC rough machining, deep hole drilling, EDM, drilling machine, high-speed milling, finishing, assembly, etc.

All of our mould steels in our company have long service life . The moulds are manufactured with advanced equipment, with a tolerance of + / - 0.01mm. The appearance of die products is good without flash, and they are well matched with other products.

Efficient equilibrium cooling system

High precision machining process

Careful selection of the steel for every part of the mold

The mold adopts the hot runner with valve gates to improve mold efficient

Product design inspection:

Whatever product design made by ism MOULD or offered by customers, we always make all round analysis and inspection, such as Plastic Mouldsing process feasibility, Plastic Moulds structure and movement feasibility, all the related plastic components matching situation, etc. It can avoid Plastic Moulds amendment, scrap and other unnecessary Plastic Moulds repair work, which are caused by product design fault. We believe that 10 more minutes we spend on the design, one month may be reduced in production.

With precise analysis, foreseeing rationality analysis for Plastic Moulds design, best processing analysis and Plastic Moulds structure application, it offers the most professional solutions with the most suitable Plastic Moulds performance and technical specification as customer required.

The inspection covers many aspects, such as Plastic Moulds intensity, mold-flow analysis, Plastic Moulds ejection, cooling system, rationality of guiding system, application of Plastic Moulds spare parts' specification, customers' machine selection and special requirement application, etc. All of these should be inspected in according with HONGMEI MOULD Plastic Moulds design standard.

Steel purchasing inspection:

There is strict inspection process and time control of spare parts purchasing, the parts' standardization, size precision, hardness of Plastic Moulds material and material flaw detection and so on.

Mould manufacture is not only mould design,CNC processing and assembly. A good mould company not only concern on this, they will pay more attention to the detail things like mold flow , mould size check, mould CNC precision, water channel check and mould polish degree.

Inspection Equipment

1. sliding caliper

2. Multimeter

3. Hardometer

4. Measure tape

5. Micrometer calipers

6. CMM machine

Appearance Inspection Standards

1. Mould base size should be standard

2. Tidy and smooth of the mould base surface

3. Mould steel must be the same as the contract

Mould Structure

1. Reasonable mould structure

2. The slides must smooth and need heating treatment,there is a oil groove on the slide

3. Lifter, insert and injection pin,bush should be operate smooth.

Cooling System

1. Reasonable cycle cooling system

2. Smooth water channel, no leak water and air

3. The interface size of the water channel should be the same as the drawing

Injection System

1. Locate ring should be suit for the injection machine, main runner size and slope should be design reasonable

2. Feeding method and branch runner should be reasonable position, the gate is easy for falling off

3. Parting Line design reasonable

4. Some mould marked date of day/Month/Year or material or logo

5. Injection Pin should be design suitable

| Product: | Plastic Mold | MoldNO: | Customized |

| Brand: | ISM | Color: | Customized |

| Placeof Orngin: | Zhejiang,China | Size: | Customized |

| Material: | Plastic | Packing: | Poly Wood Box |

| Advantage: | OEM Is Available | Shaping Mold: | Plastic Injection Mold |

| Supply Ability: | About 30 Sets Per Month | Use: | Household Product |

| Mold Material: | NAK80,S136,H13,718H,P20, etc. | ||

| Plastic Material: | PP, PC, PS, POM, PE, PU, PVC, ABS, PMMA, etc. | ||

2024/3/27 , visits

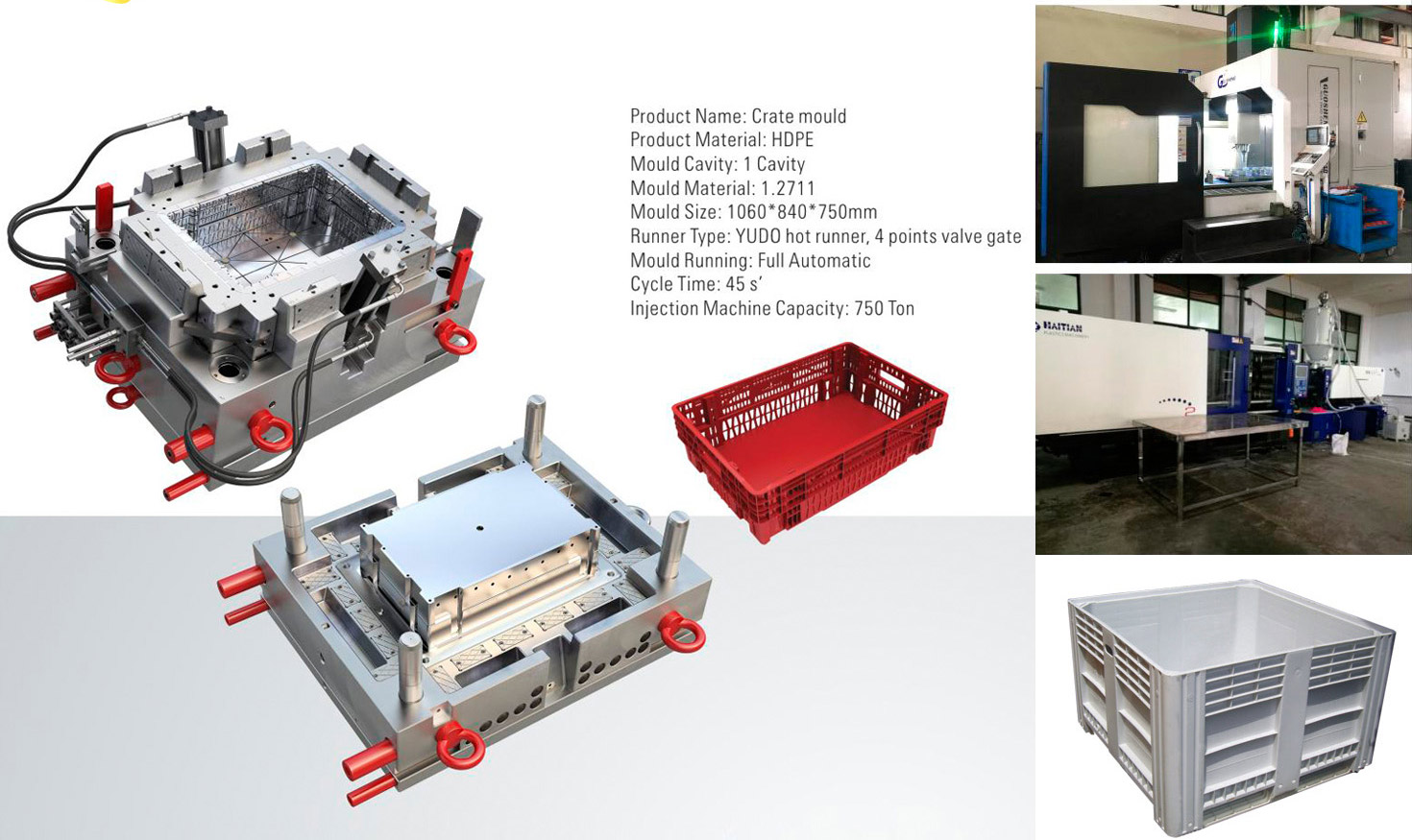

ISM MOULD manufactures moulds for Europe's largest pallet company , With the most advanced technology and perfect details .

The pallet molds produced by our company are all European standards and have a fast injection cycle : Double-face pallet mold around 100 seconds , single face pallet mold around 50 seconds .

Our professionalism is reflected in the details of each mold . If you are looking for a reliable , high quality injection /Gas-assisted pallet mold manufacturer , please feel free to contact us at any time .

More information : http://www.ismmold.com

Cel : +86 13857619260

Whatsapp : +86 13857619260

Wechat : +86 13857619260

E-mail : sales@ismmould.com

Reviews