Good mould design is the first step,PRC mould has 3 designers with more than 15 years experience.

1:We will analyze the feasibility,shrinkage and molding temperature of plastic products.

2 :We will communicate with customers,including details such as weight,style design,size and appearance,stability and wear resistance of plastic products.

3:Design and mold flow analysis are provided free of charge.

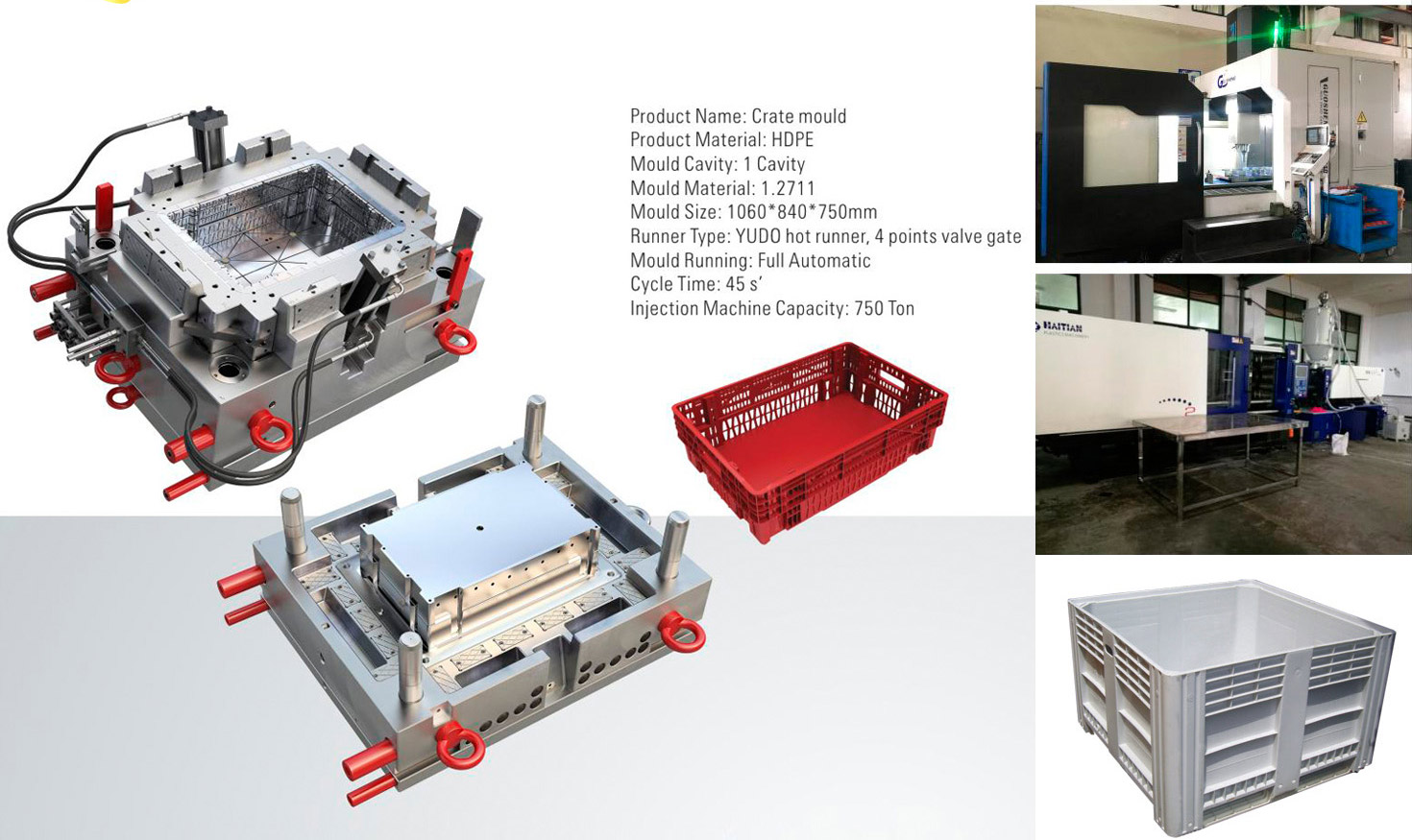

| Injection Mould Name | Plastic crate mould |

| Mould Core and Cavity Metal | P20 |

| Injection Machine Size | 800tons |

| Demould Type | Automatic |

| Metal Hardness | HRC 28-32 |

| Mould Base | Self-Made LKM DME |

| Mould Runner | Cold Runner &Hot Runner |

| Cavity Number | 1 Cavity |

| Cycle Time | 50 Seconds |

| Tooling Lead Time | 50 Days |

| Mould Life | 30-300 million shots/ 5-6years.Even in 10 years in good condition. |

| Mould Surface Treatment | EDM,Texture Mirror Polishing |

| The main mould metal material and hardness for your reference,You can choose it for your injection mould. | |||||||||

| Steel Model | S50c | P20 | 718H | 2738H | H13 | 2344 | S136 | ||

| Hardness(HRC) | 17-22 | 28-32 | 33-38 | 36-40 | 48-50 | 48-52 | 48-52 | ||

C: Mould Machine Tooling

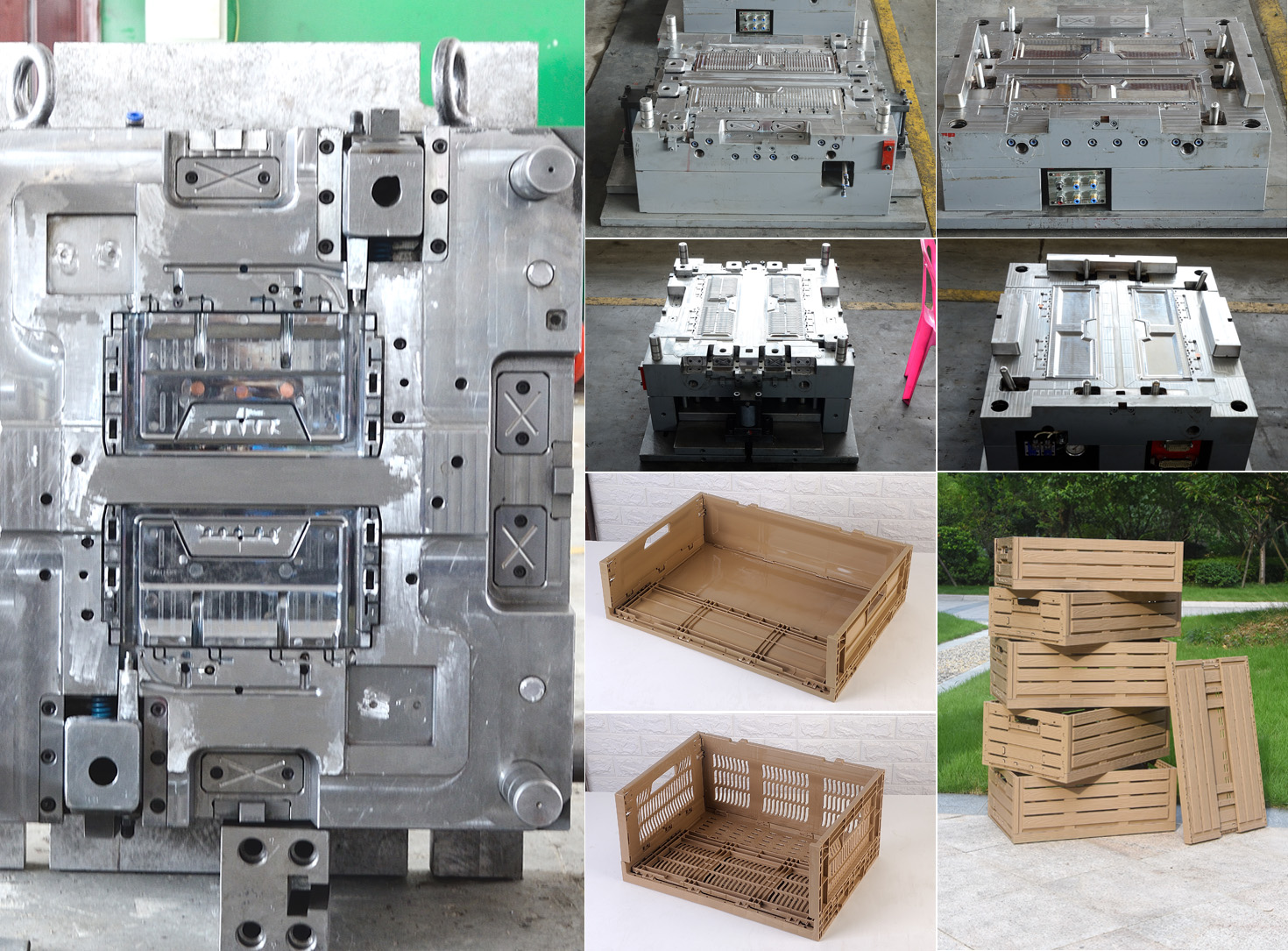

Vegetable Fruit Transportation Crate Container Mould of Plastic Injection Molds.

After the mould drawing is confirmed,start production.

Including mold steel preparation, cnc rough machining, deep hole drilling, EDM,drilling machine,high-speed milling,finishing,polishing assembly,mold trial,electroplating,nitriding,etc.

Precisely control the size,and conduct self-inspection for each mould part according to the requirements of drawing size and tolerance limit control.

D : Mould Testing

The first time test we do on the mold is to check that it moves smoothly and correctly.

After the mold is polished,we will test mould again,compare the test samples with the original design.

Then send the final samples and mold testing video to customers for confirmation.

Vegetable Fruit Transportation Crate Container Mould of Plastic Injection Molds.

E:Shipping Mould Details

1:Before the mold is shipped,we will check whether the opening and closing of the plastic mould is smooth,the water cooling system,the hydraulic oil system and the hot runner system.

2:The cavity and core are cleaned without iron filings and impurities.

3:Blow the waterway clean to prevent long-term sea transportation from rusting.

4: We spray anti-rust agent on the inside of the mold,spray paint on the outside of the mould, and apply anti -rust oil on the thimble.

5:We will put a nameplate on the mold,it shows the mould name,the year of production and mould information,mold weight and size.

6: Mould parts are provided free of charge,(convenient for customers to replace).

| Product: | Plastic Mold | MoldNO: | Customized |

| Brand: | ISM | Color: | Customized |

| Placeof Orngin: | Zhejiang,China | Size: | Customized |

| Material: | Plastic | Packing: | Poly Wood Box |

| Advantage: | OEM Is Available | Shaping Mold: | Plastic Injection Mold |

| Supply Ability: | About 30 Sets Per Month | Use: | Household Product |

| Mold Material: | NAK80,S136,H13,718H,P20, etc. | ||

| Plastic Material: | PP, PC, PS, POM, PE, PU, PVC, ABS, PMMA, etc. | ||

2024/3/27 , visits

ISM MOULD manufactures moulds for Europe's largest pallet company , With the most advanced technology and perfect details .

The pallet molds produced by our company are all European standards and have a fast injection cycle : Double-face pallet mold around 100 seconds , single face pallet mold around 50 seconds .

Our professionalism is reflected in the details of each mold . If you are looking for a reliable , high quality injection /Gas-assisted pallet mold manufacturer , please feel free to contact us at any time .

More information : http://www.ismmold.com

Cel : +86 13857619260

Whatsapp : +86 13857619260

Wechat : +86 13857619260

E-mail : sales@ismmould.com

Reviews