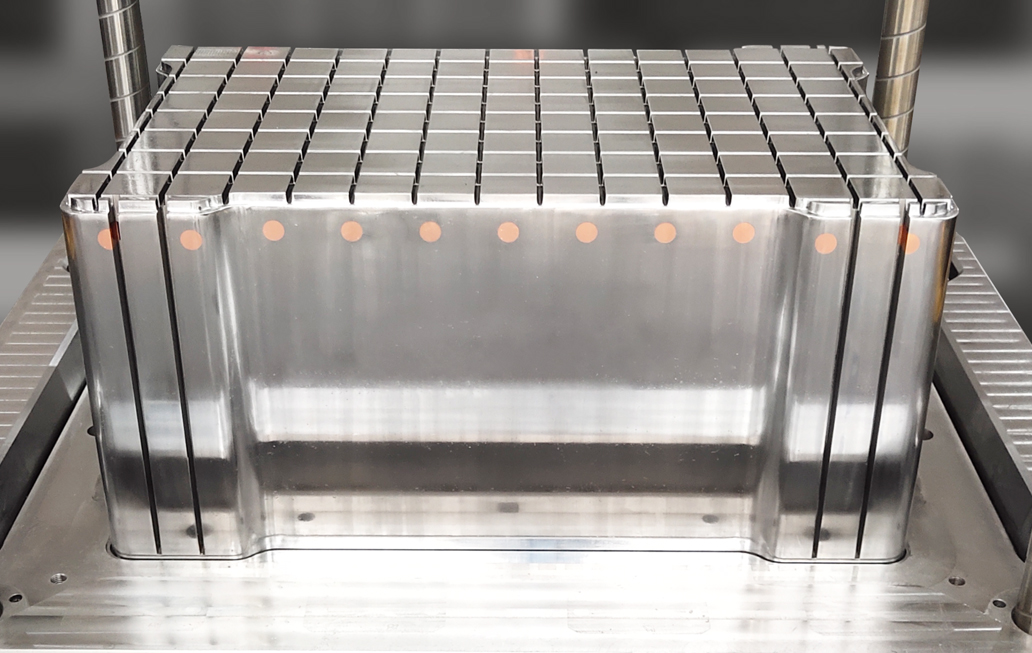

We manufacture a large number of crate plastic injection molds for a variety of applications. Possesses very mature plastic turnover box mold manufacturing technology, the main core steel is usually beryllium bronze plus DIN 1.2311 steel

ISM Mould provides customers with nearly 100 plastic Crate mould every year. ISM Mould has a very strict control system to ensure the highest quality crate molds. At the same time, in order to shorten the production cycle of plastic Crate mould, we also specialize in the production of standard molds. In this way, the quality of the plastic turnover box mold can be guaranteed, and the production cycle of the mold can be saved. If you are interested in plastic turnover box mould, please contact us to get the best price plastic Crate mould solution.

ISM MOULD manufactures moulds for Europe's largest pallet company , With the most advanced technology and perfect details .

The pallet molds produced by our company are all European standards and have a fast injection cycle : Double-face pallet mold around 100 seconds , single face pallet mold around 50 seconds .

Our professionalism is reflected in the details of each mold . If you are looking for a reliable , high quality injection /Gas-assisted pallet mold manufacturer , please feel free to contact us at any time .

More information : http://www.ismmold.com

Cel : +86 13857619260

Whatsapp : +86 13857619260

Wechat : +86 13857619260

E-mail : sales@ismmould.com

We usually use Chinese brand steel. Such as general furniture molds and daily necessities molds, we will use P20 steel; Chair, turnover box or Pallet Mould and other finer product molds use 718H. In addition, we will also use imported German steel according to customer requirements.

We use AutoCAD software for 2D drawings, and UG, CATIA, Pro-E software for 3D drawings.

Before mold production, we will send 2D/3D product modelling drawings and mold structure design drawings to customers for confirmation.

Our annual production capacity is 600 sets and more, including 300 plastic chair molds and 200 turnover box molds...

The company has technical research and development department, production center, quality inspection department, marketing department, sales department, export shipping documents and other departments, and there are 100 employees in total.

We put quality first. We carefully check the detailed specifications of the mold steel ordered with the supplier, and conduct a hardness inspection of the mold steel through professional equipment. Before providing customers with test mold samples for inspection, we will conduct multiple mold trials and modify and improve the molds, and strive to provide customers with perfect product samples.

After all product drawings are confirmed, we usually provide customers with trial samples within 50-75 days. After the customer confirms the sample, the shipment will be completed within about 5 days.