ISM Mould Make

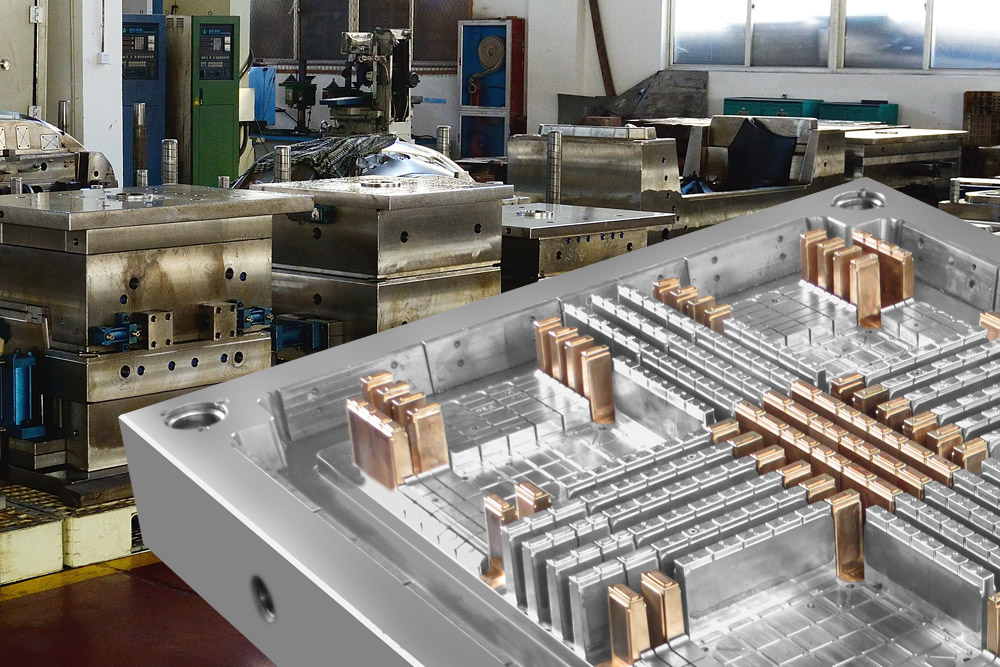

ISM MOULD has a very mature technology for manufacturing plastic crate moulds, the main core steel material of high-quality plastic crate mould is usually beryllium bronze plus DIN 1.2311 steel material. The crate mould runner generally adopts the hot runner way, which can improve the injection efficiency and surface quality of the plastic crate, reduce the injection moulding time of the plastic crates, and avoid the generation of waste when using the cold runner. We adopt the four sides angle pin and slider for taking the side core pulling, then take the stripper plate for demoulding. Plastic crate mould usually use the mould steel such as 45 #, 40Cr, P20, 2738, 2316, 718, NAK80, S136 and so on. It is generally recommended to use 718, P20 materials.

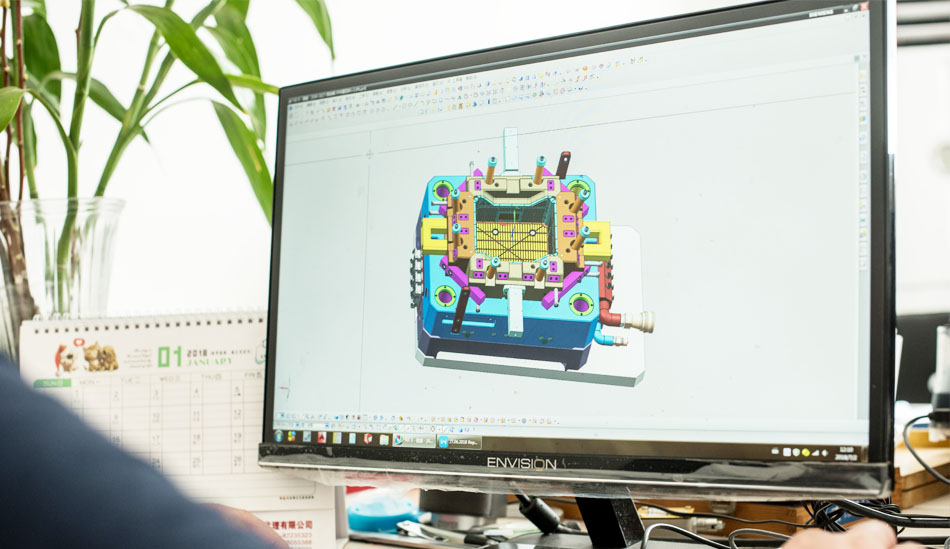

How crate moulds are manufactured at ISM Mould?

1. Plastic Crate Design,2. Developing Mould CAD File,3. Mould Flow Analysis,4.Plastic Crate Mould Tooling,5. Mould Trial Test,6. Packaging and shipment

Plastic industry crate mould (plastic folding crate mould, plastic lidded crate mould, injection storage crate mould)

Plastic agricultural crate mould (vegetable crate mould, fruit crate mould)

Plastic transport crate mould (beer bottle crate mould, fish crate mould, bread crate mould)

1. Suitable steel hardness. Excellent expertise ensures the production of plastic crate mould. And finishing the surface of the mould.

2. Precise temperature controls. Chennuo are familiar with the characteristics of plastic to produce a more durable crate.

3. Attention to detail. Optimize the handle area for extending life.

4. Excellent mould structure. Various factors, such as gates and runners, ensure that you produce plastic crates efficiently and accurately.

5. Hot runner. For example, a one-cavity plastic crate mould has a simple structure; for two-cavity and four-cavity plastic crate moulds, we use double-sided hot runners.

6. The exhaust effect of the plastic crate mould is better to avoid black spots or scorching of plastic crates;

do you need a high production performance crate moulds?

do you have the automatic ejection function problem in the 4 side collapsible core cola bottle crate mould?

do you want to try a 4 cavity crate mould with the dimension 400x300x150mm with the cycle time 32 seconds?

do you want to use the recycled plastic material to molding the one-time using crate?

A quality product comes from a good injection mould design . Our experienced team of engineers work with latest engineering tools and software helping you construct a quality plastic part . This also allows our tooling engineers to create the best and most cost effective tooling for your project requirements .

ISM Mould is an injection mold supplier with decades of experience in mold design. Our molds are precise, durable, and designed to be efficient in the manufacturing process.

ISM Mould CNC machines are very precise and have high tolerances. This service is ideal for prototyping and producing actual parts made of metal, resins or a combination of the two.

The molds developed by ISM MOULD have the advantages of high difficulty , long life ,short cycle time , reasonable price , prompt delivery and considerate service ,which are favored by customers at home and abroad

Our injection molding factory is fitted with ultra modern equipment that churns out hundreds of injection molding parts on demand. We use premium quality materials for every project.